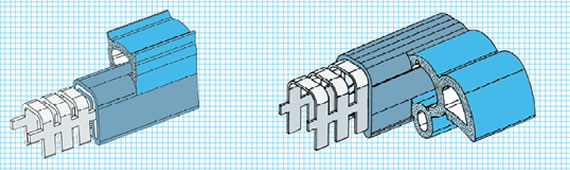

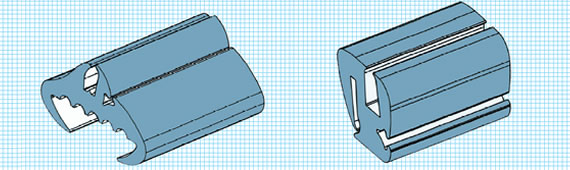

Edge Protectors and Sealing Sections

Edge Protectors are used wherever metal edges must be blunted or covered. Additmachining is not required. The edge guards also have a decorative effect and are flexible.

The U-shaped metal clamps embedded in PVC ensure that the edge guards fit securely, even when the metal edge to be covered is curved inward or outward.

The guard is simply pressed into position by hand. Tools, adhesives or other connections are not required. Edge guards are available in different shapes, sizes, colours and finishes, depending on the intended use.

Glazing and filler sections

The glazing sections shown in the catalogue show cross-sections from our standard program.

The sections marked with * in the catalogue are available from stock. We will also do custom work according to your design suggestions or our own, if required.

We would be pleased to advise you.

Qualities:

Our glazing sections are made of EPDM (APTK). EPDM is characterized by excellent resistance to weathering and ozone. Our grade does not react with paints and varnishes. Other grades, such as NBR for excellent resistance to oil, are available on request.

Tolerances:

DIN 7715, E 2, for fixed lengths;

length tolerances to be agreed.

Packaging:

Fixed lengths, bonded or vulcanised frames or rings.

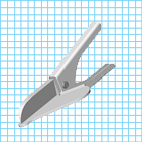

Mounting Tools

We have some fabrication tools available for professional and unproblematic mounting.

For example, our TECHNO Universal mitre-shear, which is indispensable in places where mouldings or sections made of rubber or plastic have to be mitred or cut off straight.

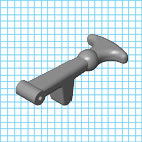

Crested Holders

Phasellus suscipit lobortis porta. Aliquam rutrum ligula sapien. Nam quis pretium nisl. Duis aliquam feugiat neque id blandit. Ut tincidunt mollis risus ut scelerisque. Mauris magna neque, elementum auctor dignissim at, dapibus sit amet odio. Quisque est dolor, pulvinar at rhoncus at, luctus a enim. Nam ac leo tellus, nec vehicula erat. Mauris euismod cursus eleifend. Donec eget vestibulum nisl. Curabitur et ante urna, ut suscipit ante.

Profiled Holders and Door Gaskets

Application:

Profiled covers, holders, shims, door gaskets (for switchgear cabinets), buffers, joint seals, hinges, decorative fillers, door frames, window guides with intermediate metal ply, with or without flocking, window guide rails with or without intermediate metal ply, flocked.

Qualities:

Rubber, plastic, aluminium, exact material names available on request.

Tolerance:

DIN 7715 E 2 rubber, DIN 16941 PVC, length tolerances for fixed lengths available on demand.

Packaging:

Fixed lengths, bonded or vulcanised frames or rings.

Custom fabrications:

If the suitable cross-sections do not suit your installation situation, then the possibility of having us manufacture a suitable cross-section for you exists.

Consult us!

We would be pleased to work out a suitable design suggestion for you. If required, we can also apply a flock coating on rubber sections.

Microcellular Rubber Sections

Round sections, square sections, and semicircular sections. All cellular rubber sections are supplied with a normal, sealed skin. For special requirements with regard to chemical and mechanical stress, the cellular rubber sections are available with a reinforced skin, with a thickness of 0.5 mm. For types with thin wall thicknesses or small cross-sections, there are limits to manufacturing with a reinforced skin.

The cellular rubber sections are also available with a cord insert in order to be able to maintain accurate length measurements. The cross-sections of the sections are also decisive here as far as the fabrication possibilities are concerned.

All the cellular rubber sections are available in fabrication lengths from 1200 mm upwards. If there is a requirement, we will also supply the material in fixed lengths or in closed rings. Under normal circumstances, the material is supplied in rolls of 20 m. Freely heated sections in rolls of 50 or 100 m.

We have the set-up for a large number of custom cross-sections. Please help yourself to the illustrations (figures). Minimum order volumes on demand.

Qualities:

a) Under normal circumstances, we supply in EPDM qualities. EPDM is an elastomer with outstanding weather- and ozone-resistance. The temperature resistance equals that of chloroprene qualities. The resistance to oil, grease and solvents is comparable to that of natural rubber.

b) If there are special requirements for oil-resistance and increased resistance to weathering, then we can also supply cellular rubber in chloroprene qualities (neoprene and perbunan).

c) In addition, there is the possibility of supplying natural rubber qualities.

Colours:

All cellular rubber items are supplied in black as a rule. Deliveries in light grey and dark grey are also partially possible, if requested. Other colours are only available in exceptional circumstances but are subject to corresponding surcharges.

Tolerances:

The measurements for the cellular rubber sections are shown excluding tolerances. The fabrication complies with DIN 7715 E3.

Packaging:

Fixed lengths, bonded or vulcanised frames or rings.

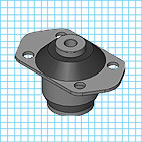

Moulded Rubber Parts

Modern laboratory, test and processing equipment enable us to fulfil diversified customer wishes in accordance with the drawing requirements.

Moulded items are manufactured according to the following processing technologies:

1. Compression moulding ( CM )

2. Transfer moulding ( TM )

3. Injection moulding ( IM + cold channel )

Choosing the most suitable manufacturing technology will ensure a gentle treatment of the material. Choosing the right tool size saves money. Large rubber parts can be made using injection-moulding machines with a capacity of up to 2.5 litres (also rubber/metal compounds using common steel grades and stainless).

We process the following rubber qualities:

Natural rubber ( NR )

Styrene-butadiene rubber ( SBR )

Chloroprene ( neoprene ) ( CR )

Nitrile rubber ( NBR )

Fluorocaoutchouc ( FPM )

Silicone ( SI )

As a result of our many years of experience, we are happy to assist you with advice. Please request our technical support.

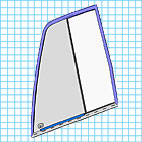

Automotive Windows

Thermally separated or normal, depending on the requirement. Surface protected using a high quality anodising bath, in the colours silver, bronze, black and gold, or with a high quality powder coating or painted in RAL shades. Use of various glass types (Single-Pane Safety Glass, Laminated Glass, sound or heat insulated glazing).

The use of light metal sliding windows is required in and around driver's cabs on construction machinery. Special technical details belong to the features of our design. These include comfortable one-hand operation, which also encompasses protection against burglars, and gives the window the perfect shaping and seal. On delivery, sliding windows are powder-coated or painted, and include Single-Pane Safety Glass, Laminated Glass or insulated glazing.

Automotive Glazing

Flat, cylindrically shaped, in Single-Pane Safety Glass, Laminated Glass or Insulated Glass.

Every type is available for every type of road vehicle, whether it's the windscreen, heated tailgate or side window; the same also applies for the railway and marine sectors.

Modern screen-printing systems facilitate all kinds of screen-printing.

Our technical department, which is supported by a highly developed CAD system, is available to assist you in finding solutions for manufacturing new products.

State of the art laboratory and test equipment ensures that all the products are manufactured in accordance with European or US standards (R43 and ANSI-DOT).